Battery Unequal Voltages In Series Strings

In a small battery with just a few cells in series, the charger voltage is divided nearly equally among the cells. For example, when charging a standard lead-acid starter battery for a car, a constant voltage of 13.5V is applied to it, and each of the six cells within it sees about 2.25V. If any cell is charged more, its voltage will be a bit higher, taking away some voltage from the other cells. For example, if one cell is at 2.5V, the other celss will be, on the average, at 2.20V. That delta voltage among cells is perfectly acceptable; lead acid cells are much more rolerant to variances in their voltage.

For another example, a small Lipo battery for a consumer product may have two cells in series. When charging with 8.4V, if the cells are balanced, each cell sees 4.2V. If the cells are out of balance, in the worst case the most dicharged cell will be at 3.3V, leaving 4.9V on the most charged one. 4.9V is above the maximum rating for a Lipo cell (4.2V), but it is still low enough that is not going to go in the thermal runawy and catch fire.

In a high-voltage battery with many cells in series, though, there is a much greater chance that the overall pack voltage is not evenly divided among its cells. Here recommend a high security lipo battery for you.

High Security Gens Ace 7.4V 1300mAh LiPo Battery

The security is the most important performance to a rechargeable battery. Without the security concern, battery will never be welcomed by people no matter how nice performance it has. Gens Ace lipo 3s 5000mah battery is the representative of li-polymer batteries. Along with the upgrading of rechargeable batteries, it is popular with more and more copter players. Li-polymer is charged with constant current and voltage. At the same time, it is equipped with a protecting circuit board to prevent the battery over charging or discharging. Besides, the outer of li-polymer batteries is with aluminum materials, which is different from the metal shell of liquid lithium electricity. Therefore, you can see the hidden trouble once the package is in deformation. Also, it will not explode but ballooning if there is any hidden problem.

Consider a 2s lipo batteries, charged up to 16.8V. If the cells are perfectly balanced, the total voltage will be equally divided into 4.2V per cell. In practice, the cells will be unbalanced, and one will be the first to be fully charged and then be overcharged. Lipo cells do not deal well with overcharging. Once charged, they cannot take more current as the other cells in series get their needed charge. Instead, their voltage rises rapidly, possibly to dangerous levels. In this example, the second cell is overcharged to 6.3V, while the other ones are around 3.5V. Despite the fact that the total voltage is 16.8V, three of the cells in this battery are not fully charged, and one of its cell is in danger of thermal runawy. Therefore, a system that relies on the total battery voltage to determine when to stop charging the battery gives the user a false sense of security; the system will overcharge some cells, and will create a safety issue as some cells with be overcharged to dangerous levels. It is therefore essential that a BMS monitor such a batter, first and foremost to prevent any cell from being overcharged, and optionally to balance the battery to maximize its performance.

Traveling with Lipo Batteries You Should Notice

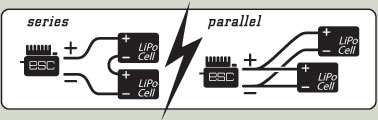

The Connection about ESC and Lipo Battery

Electric RC planes, boats and cars use batteries and Electronic Speed Controls (ESC) to control the motor. The ESC has two sets of leads, one runs to the motor, the other set to the battery pack. While it can be advantageous to solder the motor to the ESC, the same is not true for the battery. LiPo battery packs are rechargeable and need to be removed from the RC vehicle before charging. Some LiPo packs come with a connector already installed, others with nothing but a pair of wires.

What is an ESC?

ESC stands for Electronic Speed Control. Either the flight controller or radio receiver sends signal to the ESC, and the ESC drives the brushless motor by providing the appropriate level of electrical power.

The ESC thinks it is connected to a LiPo battery because it was programmed that way. Low Voltage Cut off (LVC) reduces power to the motor when the voltage drops to a pre determined level (usually 3V per cell for LiPo) to prevent damage to the battery. If you are not using a LiPo you need to disable this functionality. In the manual for the ESC there is a programming procedure which can disable this.

A 3s lipo is 12.6v fully charged, a fully charged 12v lead acid is higher then that, so the ESC probably thinks you connected a 2200mah 3s lipo. The LVC for a 4s would be 3v x 4 = 12v. When your motor starts pulling amps the voltage drops. It will quickly drop below 12v with how many amps you are trying to pull. This will trigger the LVC which will drastically reduce power to the motor.

ESC refresh rates vary. For multi-rotors, given the balance of multiple motors critical to the craft's ability to stay airborne, high refresh rates are more important than many other hobbies where ESCs are used.

The only other major factor to consider is an ESC's maximum current rating, which must exceed the current draw to each motor. Generally, 30 A for medium/large quads and 10 to 12 A for a small quad is plenty.

Clearly, those are high current draws. But such is the nature of multi-rotors. A medium-sized hex can easily pull 40 A on a steep ascent. As a result, hefty batteries are a necessity for decent flight times.

The industry standard is lithium-ion polymer (LiPo) batteries. Relatively lightweight, compact, and offering high discharge rates, LiPos are well-suited for multi-rotors.

There are three to consider as you start perusing the cyber-aisles of LiPo batteries. The first is voltage. A single cell supplies a nominal voltage of 3.7 V (4.2 V at full charge). Each additional cell wired in series adds 3.7 V to the nominal voltage of that pack. Cell counts are denoted by the number of cells followed by "S". A cheap 2s lipo batteries, therefore, is a battery of four 3.7 V cells at a summation of 14.8 V.

LiPo packs also have C ratings that indicate the maximum rate at which a pack can be discharged, with C standing for capacity. A 20C pack can be discharged at a rate 20 times its capacity.

Capacity, therefore, is the third important factor. It's measured in milliamp-hours (mAh). Let's say our 20C pack has a capacity of 4000 mAh. Given what we know about C ratings, we can do the math and determine its maximum discharge at up to 80,000 mA, or 80 A. Similar to ESCs, you need a discharge rate that's higher than the combined draw current of your motors.

How to Connect ESC to a LiPo Battery

Following the instruction to connect ESC to Your Lipo battery

Instructions

- Use your volt meter to determine which lead is positive and which is negative from the battery. If you reverse polarity to the ESC it will either damage the ESC or simply not work.

- Look at the wires attached to the ESC, there should be a + and - screened onto the board to indicate the proper polarity. Brushless ESC's will have three wires running to the motor and two wire to the battery, however, brushed ESC have two wires to each device. Be sure you are working with the battery wires.

- Select the type of connector you want to use, most hobbyist use Dean's connectors. There is a male end (has prongs protruding) and a female end (has sockets that accept the prongs) connectors. It is common to place the female connector on the battery and the male on the ESC.

Strip about a quarter inch of insulation off each of the four wires. Place a 1-inch long piece of heat shrink tubing on each wire. Place the heat shrink as far from the bare end of wire as possible.

Solder the connectors to the wires. Make sure the prongs and sockets align properly to keep the polarity correct. Once the solder has cooled slide the heat shrink tubing over the solder. Use a match or lighter or even your soldering iron to shrink the tubing tight.

How LiPo Battery Packs Are Sized

There are lipo battery sizes ranging from tiny one cell packs for micro flyers to mulit-cell batteries for large scale electric powered planes and heli's. The voltage and capacity of any size battery pack depends on the capacity of each cell and how they are wired together.

To understand how LiPo battery packs are sized, you need to have a basic understanding of voltage and capacity. If you're not that familiar with batteries, that's OK. Just think of voltage as the "muscle" and capacity as the "energy" of a battery. At firs, you should know what is the lipo battey voltage.

LiPo Cells in Series Increases Voltage

To build voltage, cells are added together in series. The voltage (muscle) of the LiPo battery pack will continue to increase as more and more cells are added in series.

Battery packs achieve the desired operating voltage by connecting several cells in series; each cell adds its voltage to the total terminal voltage. Parallel connection attains higher capacity for increased current handling; each cell adds to the ampere/hour (Ah) count.

Some packs may consist of a combination of serial and parallel connections. RC batteries commonly have four 3.7V Lipo cells in series to achieve 14.4V and two in parallel to boost the capacity from 2,400mAh to 4,800mAh. Such a configuration is called 4S2P, meaning lipo battery 4s in series and two in parallel. Insulating foil between the cells prevents the conductive metallic skin from causing an electrical short.

When connecting cells in series, it is the other way around, where tight capacity tolerances (mAH) are HUGELY important, while voltages are not. For instance, a 2200mAH 2S battery can be connected in series with a 1S 2200mAH battery of the same age. 2S lipo battery is made up of 2 cells in series, and thus the whole system is like a 3S battery. However, again do not use different battery chemistries or capacities in this config. Also if you plan of charging or discharging at high currents, you will need to keep the batteries balanced since there is always a bit of play in the capacities of the cells and one cell will always die or charge faster than the others. In series, that is especially bad if nothing is done about it, it means the battery with the least capacitance will be stressed the most, causing it to become even worse and possibly damage it or destroy it! (it is a positive feedback loop or a chain reaction type effect). Just make sure to keep them balanced.

LiPo Cells in Parallel Increases Capacity

To build capacity, cells are added together in parallel. The capacity (energy) of the LiPo battery pack will continue to increase as more and more cells are added in parallel.

But the voltage (muscle) will NOT increase as cells are added in parallel.

Total Voltage = 3.7 V

Total Capacity =2100mAh + 2100mAh + 2100mAh = 6300mAh

With 2 3s 1300mah lipo packs in parallel you would have one 3000mAh 20c pack. The C rating does not double like mAh in a parallel battery circuit. You can load up the batteries more in this configuration though. Where, individually, the 1500mAh 20C packs have a constant discharge rating of 30 amps, the "new" 3000mAh 20c pack has a constant discharge rating of 60 amps.

Right Size Pack for Your RC model

Choosing the correct battery pack is as easy as 1-2-3. Most of the current LiPo battery packs of the countless manufacturers sport common dimensions meaning you can easily replace that gnarly NiMH pack with a super-duper LiPo battery. Many model manufacturers offer their own line of hop-up packs to switch from NiMH to LiPo with no problems. Often, when you look closely they offer some sort of 'hop-up' sections where they promote their products on their websites. Just have a look first and see what the model manufacturer has to offer. Most of the time you find optional battery packs very easy and you are also ensured that the pack(s) you buy fit your models chassis just right.

The next tricky part in choosing the correct pack are the overall dimensions of the battery. If the battery you want to replace is of the usual 7.2V Sub-C style than the alternatives are quite clear. You need a pack not longer as 140 mm, not wider as 46 mm and not thicker as 24 mm. These standard dimensions are featured by most battery packs and make swapping easy. If you need special batteries, for example for smaller 1/16 or 1/18 scale models than 85 x 29 x 17 mm are the numbers you need to take care of. But remember: what we tell here is just a rough guide line! Always double check with the actual batteries you use to make sure to order the correct items.

If you look for a battery pack to suit your monster or Short Course truck or even the new generation of 1/8 scale electric off-road buggies the choice is quite easy as these often have rectangular battery compartments. Just measure what the maximum dimensions of the battery compartment are (length/width/height) and have a go on whatever product suits your needs. When it comes to battery packs for the above models many manufacturers offer special solutions for trucks like the Traxxas E-Revo, Mini Revo etc. Again, just have a look around the specific websites and most of the time you will find what suits your needs.

LiPo Battery Cell Count Charge Supports

There are maximum and minimum LiPo cell count, the battery charger can handle. For instance some battery charger supports up to 6S Lipo, some even up to 8S Lipo, but they might not be able to charging 1S LiPo. Ensure you understand what cell count the charger supports.

Charge Current Rate

Choosing the correct charge current is also critical when charging RC LiPo battery packs. The golden rule here is "never charge a LiPo or Li-Ion pack more than 1 times its capacity (1C)" . For instance a 2000mAh pack could be charged at a maximum charge current of 2000 mA or 2.0 amps.

But things are changing and many battery manufacturers allow higher charging °C current. Most LiPo experts feel that you can safely charge at a 2C or even 3C rate on quality packs that have a discharge rating with a minimum of 20C or more, with little effect on the overall lifetime of the pack, so long as you have a good charger with a good balancing system.

For instance a 2000 mAh 14.8v lipo pack, could be charged at a maximum charge current of 2000 mA or 2.0 amps. Never higher or the life of the pack would be greatly reduced. When you purchase a charge rate significantly higher than the 1C value, the battery will heat up and could swell, vent, or catch fire.

Remember, the three main things that shorten LiPo battery life are:

- Heat

- Over Discharging

- Inadequate Balancing

Maximum Charge Voltage and Current

A 3.7 volt LiPo cell is 100% charged when it reaches 4.2 volts. Charging past that voltage will destroy the cell, and possibly cause it to catch fire. This is really important to note and keep in mind all the time. A computerized charger will stop the charge process when the battery reaches 4.2V per cell. A balancing computerized charger will do this for each individual cell.

It is critical that you use a charger specified for Li-Po batteries and select the correct voltage or cell count when charging your LiPo batteries if you are using a computerized charger. If you have a 5000mah lipo 2s you must select 7.4 volts or 2 cells on your charger. If you selected 11.1V (a 3S pack) by mistake and attempted to charge your 2S pack, the pack would be destroyed and most likely catch fire.

LiPo batteries are often recommended to be charged at 1C current rate for various reasons, although some more expensive LiPo batteries these days are advertised as fast charging, which can be charged at 2C or even higher. The key reason for charging at lower current is safety, and to avoid the battery gets too hot, which can cause the battery to go puff and shorter battery life.

Basically, to charge at 1C, it means if you have a 3S 2000mAh LiPo battery, your charge current would be 1 x 2000mA = 2A; But to charge at 2C, the charge current is 2 x 2000mA = 4A.

When selecting a battery charger, The manual should specify what the maximum charge current is. If a low charge rate charger is used, charging will take longer. It's completely fine if you don?ˉt mind spending more time waiting.

Sometimes the charger might say the max charge current is 6A, and your battery is also fine to be charged at 6A, but it doesn?ˉt necessary means you are able to charge at this rate. It also depends on your charger power and the cell count of your LiPo battery. In the next chapter we can find out about why and how to choose charger power wattage.

A Revolution in RC Battery Technology

The revolution motors was accompanied by a revolution in battery technology. The energy density of modern lithium-polymer (LiPo) batteryies, combined with the amount of power they can provide at very cheap prices, has opened the door to a new class of aircraft. With this comes a warning: Lipo batteries can catch fire in very dynamic ways from charging, physical damage, or a change in the wind. A great idea is to have a collection of clay flowerpots in which to store and charge batteries. Don't let the batteries get hotter than 120 degrees Fahrenheit or freeze.

A common way to destory a battery is to leave it plugged in to the speed control when the plane is not being flown. If the battery is discharged too deeply. It will destroy the battery.

At the Brooklyn Aerodrome, we have settled on the 1800-milliamperehour (mAh) or 1.8-amperehour lipo 2s battery pack because such battery packs are cheap and are around the correct weight to balance the Flack. For the more creative aircraft, such as the Bat, we double up battery packs for nose weight and will add lead tire weights if needed. It is easier to have a standard size and work around it than to have varying capacities that inevitably will have you at the flying venue with the wrong-sized battery pack. The other considerations around batteries are the speed-control connector and the balancing connector.

Recommend LiPo Battery pack

Genstattu.com has the least-expensive battery packs historically, and they perform okay. I use very high-quality Gens Ace 5s lipo battery packs that have not puffed out despite being five years old, but that is the difference between an $8 to $9 battery and a $30 battery. I suggest going cheap with low expectations. Lots of brands are available, but try to buy from a U.S. warehouse to minimize shipping costs and transit time.

|

| 3S Gens Ace 5000mAh |

Currently, I use the Gens Ace 1800 mAh 2S1P 20C (U.S warehouse) at $8 to $9. This battery lasts about one to two years if treated well and has shown itself to be crash-tolerant. It has a JST-XH connector for charging and a male XT60 connector for powering the airplane. Be mindful of these connectors when buying chargers, and you will have to buy and solder a male XT60 connector onto your speed control.

Alternative Batter Packs

Any two-cell LiPo pack with a 20C or greater rating will do. BP Hobbies offers the Cheetah Packs 7.4V 1800 mAh 35c LiPo battery at $16 with JST-XH connectors for charging and Cheetah 4.0-mm controller connectors.

Be aware that lithium-iron-polymer (LifePo) and lithium-iron (LiFe) batteries are now being sold that look very much like LiPo batteries but differ in a few ways. They have a lower voltage (6.6 volts versus 7.4 volts for LiPo), so if you go with these, be sure to go on ghe higher end of kilovolt ratings for the motor - 1800 kilovolts is about right - and consider using a 10-inch prop where I have been recommending a 9-inch prop. These batteries also will require a charger that is designed for them. A major advantage of LiFePo batteries is that they are less likely to catch fire.

Discussion About Lipo Battery Internal Resistance

IR is a window to the inside of your battery and tell you the overall battery health. It wilt el you how strong or weak it is, how it will perform, and when your battery is sick and dying in need of replacement. OK for Ri to be useful you have to establish a Baseline Reference. To do that certain conditions have to be met in order for the readings to be meaningful and useful. All that means is we are going to start with a new battery, fully charged, well rested, at a specific temperature like room temperature. Don’t worry if the battery is not brand new, you can still do this, it just will not be as meaningful starting with a tired battery because you will not know what it was when at peak or new condition.

A new battery contrary to what you may have heard needs to be broken-in by a few gentle charge discharge cycles. By gentle I mean 1C charge/discharge rate. Take your new battery and fully charge it up at 1C allow it to rest to come to room temp, measure the Ri with your charger, record the reading. Now discharge it down to 3.2 vpc and note AH capacity. Recharge full, rest, measure Ri, and repeat a few times. What you will notice is the Ri will slightly decrease and stabilize, and the AH capacity will slightly increase and stabilize. This is your Baseline Reference of when you battery is new in 100% tip top shape.

How to Measure Internal Resistance in Packs

If you have, for example a 1000ma 10C 3-cell Li-Po battery, you need to load it to a couple values to get an accurate internal resistance. First you need to put a relitively small load on the battery, around 1C, and measure the actual current from the battery and the actual voltage across the battery. For a 3-cell 1000 ma battery, you would need to use a load with a value of around 12 ohms. Since the voltage of a freshly charged 3-cell Li-Po is about 12 volts, a 12 ohm load will pull about 1 amp which is 1C for a 1000ma 7.4 lipo battery. The load will need to dissipate at least 12 watts, so you would need to use a resistor rated for at least 20 watts to keep it from overheating.

Lets say that this test gives you a voltage of 11.20 volts and 0.98 amps of current.

Next you want to load the battery close to it's maximum C rating. To load our 5000mah lipo battery to 10C we would need to pull 10 amps, since the 3-cell battery loaded down this much will probably have a voltage of around 10 volts, it would take a 1 ohm load to pull 10 amps. 10 amps at 10 volts is 100 watts, so it will take a pretty big resistor to dissipate that much heat. Again you will want to measure the voltage right at the battery and the current being pulled from the battery during this test.

Let's say that in this test we measure 9.97 volts and 10.11 amps. Now that we have these 2 data points, we can calculate the internal drop of the battery and calculate the internal resistance.

The difference in voltage between the 2 tests is 11.20 - 9.97 or 1.23 volts. The difference between the current in these 2 tests is 10.11 - 0.98 or 9.13 amps. Now using Ohms Law, we can calculate the resistance. In this case it would be the voltage difference divided by the current difference or 1.23/9.13 which equals 0.1347 ohms for the entire pack. Dividing this value by 3, since there are 3 cells in the pack, yields an internal resistance of 0.0449 ohms or 44.9 milli-Ohms per cell.

Does LiPos with Higher IR Affect Capacity?

The internal resistance (IR) will not affect the capacity of the pack but rather its capability to deliver at higher rates. Well, here is an example for you. You have a 1000 gallon water tank with a 3" drain valve (low resistance) and a 1/2" drain valve (high resistance). You use this tank to water your 20 horses. The capacity of the tank remains 1000 gallons regardless of which drain valve is open but the 3" valve can water all 20 horses simultaneously while the 1/2" valve can water only 1 horse at a time. Obviously that is not a technical description and there are dozens of factors and exceptions to every rule but that is it in a nutshell without all of the technical jargon.

I have tested one pack that was identical in weight to a "standard" 3S 2200 that delivered over 2800mAh at very high rates (approx 30C) BUT it got very hot.

The verifiable fact is that the IR of LiPo packs will vary enormously with temperature and different packs have different curves. And they may cross. One pack that is physically identical in size and weight to another can have an IR that is much higher at low temperatures (say 20˚C) than the second but that is significantly lower at high temperature (say 60˚C). Yet at the same time their capacity is identical over a range of discharge currents.

Most decent higher capacity and higher discharge rated LiPo cells will have roughly 2 to 6 milliohms (0.002 to 0.006 ohms) of internal resistance when brand new. To calculate the total internal resistance of a series wired pack, you would then add these numbers together so a 4S pack with each cell having 4 milliohms of resistance will show a total internal resistance of about 16 milliohms (0.016 ohms).

Lipo Battery Load Testing You Should Know

Note that the battery may appear to have a greater capacity when it is discharged intermittently than it may have when it is discharged continuously. This is because the battery is able to recover during the idle periods between heavy intermittent current drains. Thus testing a battery capacity with a continuous high current drain will not necessarily give results which represent the capacity achievable with the actual usage profile.

Load testing is yet another way of testing a battery. Load test removes amps from a battery much like starting an engine would. A load tester can be purchased at most auto parts stores. Some battery companies label their battery with the amp load for testing. This number is usually 1/2 of the CCA rating. For instance, It is 4000mah 80C made 2011 weight 127 gr/cell full discharged 200 Amps. It is 3s 2200mah lipo made 2012 weight 133 gr/cell full discharged 275 Amps. A load test can only be performed if the battery is near or at full charge.

We decided the only way to get some answers was to put a few batteries under a serious high load and see what squeezes out. Regardless of what the manufacturers imply with their high C ratings, even a gold plated battery pushing 200 amps through 10 gauge wires will melt the solder off the junctions. A case in point is the first test of Gens Ace 5000mah, 65C, RC 2s lipo batteries showed that the 4mm bulleted split pack link connector melt off their wires at the equivalent of 32C.

Higher charge rates will only improve performance if you run the pack as soon as it's off the charger as this will result in slightly higher cell temps which reduces the IR. You could charge a pack at 1C and then put under some lights or other heating source and get the same results as charging at higher rates depending on how hot your heat source is getting the pack. I have come to the conclusion that in a hardcase 2S pack the maximum C rate possible is 35 to 40C if the pack has 5000mAh. If the pack has 6500mAh it will have 25 to 30C.

Voltage available under high load was another area of question. I've seen ESC's cut out when the throttle is opened past 75% because a crap battery couldn't keep up with a motors current demand so the ESC shuts down on low voltage. So what's a "respectable" percentage of voltage a battery will hold under load? Does one hold 5% voltage reserve at WOT conditions while another will hold 25%?

To get a start at some answers I built a box that puts a constant resistance across the batteries terminals. Using OHM's law and 6S as my standard I calculated what the nominal current should be and provided a number of different "taps" or resistances I could plug into. The resisters are large spiral types that act like a powerful heater so 1200 SCFM of air is blown over them during testing. While the batteries are under load the voltage, current and temperature are recorded. A common lipo tester is plugged into the balance taps so the actual percentage of voltage remaining is displayed.

There are the caveats: This is called "resistive" loading. When we run our motors we are putting them under an "inductive" load which is a different kind of load. A resistive load will tell you alot but there will be difference in the results. Also differences whether the load is pulsed or sustained, etc. Therefore the second half of this posting will be with an inductive load producing tester.

Why Lipo Battery Is Different from Ohter Battery Types

Modern Lithium Polymer batteries (LiPo, Li-Poly) are able to store and deliver large amounts of energy from light-weight packs. Think of and treat LiPo batteries as fuel. Lithium Polymer cells, as with any high energy source (petrol, electricity, gunpowder etc) must be handled with appropriate precautions and care. Lithium Polymer batteries have been proven world-wide to be a practical and enjoyable power source for model aircraft.

Modern Lithium Polymer batteries (LiPo, Li-Poly) are able to store and deliver large amounts of energy from light-weight packs. Think of and treat LiPo batteries as fuel. Lithium Polymer cells, as with any high energy source (petrol, electricity, gunpowder etc) must be handled with appropriate precautions and care. Lithium Polymer batteries have been proven world-wide to be a practical and enjoyable power source for model aircraft.

LiPo batteries may take a wide variety of shapes due to the gelling agent separating the cells. Machines and tools with strange sizes and shapes often use LiPo batteries for this reason. However, because they are stronger and potentially more dangerous than other rechargeable batteries like NiCd or NiMH batteries, special care must be taken.

What is the composition of a Lipo Battery?

LiPo battery consists of one cell or 2 or more cells connected to provide a specific voltage and/ or current capacity. The battery is interfaced into an AV using a basic connector, such as a Deans. The connector consists of a red (+) and black (-) lead as well as a Cell Balancer Connection.

Each cell in a multi-cell LiPo pack is rated for 3.7 volts and requires a charging voltage of 4.22 volts. When operating with a LiPo battery it is EXTREMELY important that you do not allow any cell to drop below 3 volts. Discharging a LiPo cell to less than 3 volts can cause irreparable damage to the internal chemistry causing dramatic reduction in battery life, charge capacity, and discharge time.

It is not uncommon for individual cells in a battery pack to discharge at different rates over the duration of a flight. Cells may vary in voltage by a couple tenths of a Volt during discharge. It is important to program your transmitter or Autopilot to alert you before a cell drops below 3 volts. A LiPo cell has a nominal voltage of 3.7V. For the 2s lipo batteries above, that means that there are two cells in series (which means the voltage gets added together). This is sometimes why you will hear people talk about a "2S" battery pack - it means that there are 2 cells in Series. So a two-cell (2S) pack is 7.4V, a three-cell (3S) pack is 11.1V, and so on.

Special Considerations when Using LiPo Batteries

The main concern that people using LiPo batteries have is that they have a tendency to explode. This is an obvious problem and means that extra care must be taken to prevent this from occurring.

General usage tips:

1.Lithium batteries don't work well in cold air. If you are flying in the winter keep the batteries in your car for best performance.

2.Don't let the batteries overheat. Try and keep them under 140-160 degrees F. This will prolong your battery life.

3.Don't push the batteries past their rated maximum C rating. This will damage the battery and the apparent capacity of the batteries will drop. If when you recharge you are only putting ½ to ¾ of the rated capacity back into the batteries you are probably pushing them too hard.

4.If your building your own cells then put spacing between each cell in the pack to help cooling of the pack. This is most important when building packs larger than 2 cells.

5.Some LiPoly cells use aluminum tabs that you must solder to. Normal soldering procedures will not work on aluminum. You'll need to purchase aluminum soldering paste. The vendor where you purchased your aluminum tab cells should stock this paste.

Lipo battery Voltage and Capacity

When talking about a LiPo, the primary characteristics to understand are the battery’s voltage and capacity. This is typically noted in a shorthand such as “4S-2200”. In this example, “4S” denotes that the battery has four cells in series. The nominal voltage of each cell is 3.7 volts (4.2v fully-charged), so the total pack voltage is:

4 cells x 3.7v = 14.8v.

The second number denotes the capacity of the battery in milliamp-hours (mAh). A fully charged 2200mAh pack is rated to provide a current of 2200 milliamps (2.2 amps) for one hour before it is fully discharged. This capacity value is completely independent of how many cells are in series. In simple terms, the capacity value allows you to estimate how long a battery will provide useful power in a given application. In practical terms for RC use, the capacity rating is typically only helpful for rough comparisons of different batteries. i.e. a 2S lipo battery 5000mah will provide about double the run time of a 2S-2500 lipo in the same RC car.

A 4S2P-2200 battery would consist of two 4S-1100 batteries wired in parallel to provide a total 2200mAh capacity. All other things being equal, you would care for and use this battery the same as you would the previous 4S-2200 example (which is really a 4S1P-2200, but we ignore the 1P). There may be a difference in physical size, but a 4S-2200 and a 4S2P-2200 are functionally equivalent. The differences will really only matter to the guy at the factory who has to assemble the battery.

Check for Lithium Cell Balance

Before charging a new pack, check the voltage of each cell in the pack individually by using the taps. Keep a record and check every tenth use cycle. An unbalanced pack, or a pack with voltage levels not within 0.1 volts of each other, may catch fire. If the pack becomes unbalanced after every discharge, it should be replaced.

Do Not Charge Batteries Unattended

LiPo batteries don't take too long to charge, but there should always be someone near the battery and charger to make sure nothing bad happens. This is very different from other rechargeable batteries, which are more set-it-and-forget-it products. Charge in an open, ventilated space on a safe, fire-retardant surface such as a fire-safe Pyrex dish with sand or a fireplace. Keep a bucket of sand nearby in case a fire starts. If it does, dump the sand on the fire to put it out.

Life of Lithium Polymer Batteries

A Lithium Polymer battery needs to be replaced when it holds 80% or less of its capacity. If used at the maximum continuous discharge rate on every cycle and every charge is at 1C or greater and it’s used down to 3.00V per cell under load (when your LiPo compatible ESC cuts power to the motor) then don’t expect to get more then 40 or 50 cycles from your LiPo Pack. Please see my guide to prolonging the life of your LiPo’s.

The Experience about Parallel Charging My LiPo Batteries

What is parallel charging?

In a nutshell parallel charging allows for multiple same cell count batteries to be connected in parallel to create a single larger logical battery that can then be charged. The following is my experience about lipo battery parallel charging.

With cells in series, and no balance lead, your charger has no idea how much voltage is in an individual cell; it only knows the total voltage. If it reads 7.4V, that might be cell 1 with 4.2V and cell 2 with 3.2V, or it might be cell 1 with 3.7V and cell 2 with 3.7V, or it might be something else. Unless the charger connects to the balance lead, it just doesn't know. So, let's imagine it's the first case. You start charging, with cell 1 at 4.2V and cell 2 at 3.2V, and the charger says, "ok, I need to see 8.4V before I stop, so I've got a long ways to go," when in actuality it is going to overcharge cell 1 and possibly blow it up or catch it on fire, and definitely it is going to ruin or at least damage cell 1 at a bare minimum. That's where active balancing comes in. Cells in series must be *actively* balance by a smart charger, to get them to be equal.

However, here's what you're missing still: cells in parallel do *not* need active balancing by a smart charger. Rather, they naturally, by the laws of physics, will perform passive balancing. Cells in parallel automatically, passively, due to voltage gradients (differences), self-balance until they are equal. If you take 2 individual LiPo cells, and place them in parallel, and wait long enough, no matter what voltages they *were*, they will equalize, automatically, to become *equal* voltages over time. One will discharge into the other, until they are equal.

However, here's what you're missing still: cells in parallel do *not* need active balancing by a smart charger. Rather, they naturally, by the laws of physics, will perform passive balancing. Cells in parallel automatically, passively, due to voltage gradients (differences), self-balance until they are equal. If you take 2 individual LiPo cells, and place them in parallel, and wait long enough, no matter what voltages they *were*, they will equalize, automatically, to become *equal* voltages over time. One will discharge into the other, until they are equal.

So, in your case of 3s 2200mah, when you place the whole packs in parallel, and the balance leads in parallel too, cell 1 of pack 1 is placed in parallel with cell 1 of pack 2, so both cell 1's will automatically, by the laws of physics, passively balance until they are equal. Both cell 2's will also passively balance until they are equal, since cell 2 of pack 1 is also in parallel with cell 2 of pack 2. However, both cell 1s (as if a large single cell) are still in series with both cell 2s (as if a large single cell), so *active* balancing is still required here, to get the cells in *series* actively balanced, and that's where the smart charger does its job.

Therefore, when charging in parallel, you are still getting all 4 cells to be balanced, just as if you were not charging in parallel.

What are some specific uses of parallel charging?

450 sized heli:

Many times people start with a 450 sized heli and in the beginning they can not get enough flight time. This is what we call the "Welcome to your new addiction" stage. Parallel charging can be a great aid to the new pilot. For example with a 350W charger a 6x parallel lead set, a new pilot could charge 6 450 packs in 30min.

700 sized heli:

Larger electric helis are becoming very popular and they come with large needs in terms of power. A common battery pack for a 700 is a 2s lipo 5000mah made up of (2) 6s 5000mAh packs wired in series. Due to the lack of 12s chargers available, a need for charging pairs of large 6s packs has arisen. Of course you could use 2 chargers, or a dual port charger, but there is another solution, a solution that really brings out the best on the new powerful chargers offering 1000W or more of output. By using one of these new 1000W chargers and parallel charging, you can charge a pair of 6s 5000mAh packs in 25min or less.

Remember to be careful about large voltage gradients (differences), however, as the passive balancing can be quite fierce (and potentially damaging or even dangerous), if cell voltage differences are too great before being placed in parallel--refer back to my article for warnings & recommendations on this.

My DIY Lipo Battery Back Experience Share for You

Superior monolithic battery may not produce high quality Lipo battery pack for RC aircraft, but excellent RC aircraft battery pack necessarily need superior lipo cell to produce. This is particularly true if you need a battery pack to regularly power equipment such as remote controlled (RC) cars or aeroplanes. Batteries such as nickel cadmium (NiCad) or nickel metal hydride (NiMH) are popular choices for RC car enthusiasts, while lithium polymer (LiPo) batteries are chosen by RC aeroplane enthusiasts, due to the that battery's lighter weight and higher output voltage. Make a rechargeable battery pack wired in series to increase output voltage: RC models need about 10-volts to operate, although it varies by type. Wiring in series combines the output voltage of each battery in the pack.

I have two 6S 5000mah 3s lipo packs. One pack has one defect cell. I remove the defect cell and one of the good cells from the defect battery pack and thus get a 4S pack.

I connect the 6S and 4S packs together in serial to get a 10S battery pack. Wiring diagram is shown below.

I also cheek each battery pack using RC LI-Po battery tester. The RC Li-Po tester clearly indicates how many cells there are in the battery pack (including the Voltage of each Li-Po battery cell). However, this particular RC Li-Po tester can only test up to 8 battery cells. Fully charged battery cell has a voltage of nearly 4.2V. The pictures below depict the testing of a 6S (number of cells) and a 4S (voltage of a single cell in a pack) battery pack. When I connect everything together, I get a 10S 5Ah 36V Li-Po battery pack. I put the pack into the triangle bike bag for easy fitting on to the bike. Total weight of the battery pack is only 1,42 Kg.

So far in the auctions I have won on Genstattu, I have paid an average of $8.94 per cell, including shipping and handling charges! The 7.4v 2s lipo that I will build in this How-To cost me a grand total of $54.87 including the cost of the 6 cells, the Deans Connector, the 12 gauge wire and the tape used to hold everything together. If you decide to add a balance connector, this will add about $2.00 to the cost of the build.

The 6 cell pack built here has a open circuit voltage of 6 x 3.7 volts per cell for a total pack voltage of 22.2 volts, and has a capacity of 2300mah. The pack can deliver 30C continuous (69 Amps) with burst capability of 40C (92 Amps). I am currently running them in my 150% F-4 and 166% F-18 ParkJets and in both planes I am pulling 35 Amps (15.2C), and getting 5-6 minute flights with 300-400mah left in the lipo battery pack at the end of the flights. At this current draw, the Gens Ace 6-cell pack delivers 22.2 volts or 2.867 volts per cell. In this application, the packs are delivering 22.2 volts x 35 Amps or 602 watts, which is pretty good for a battery pack that weighs just 1 pound!

I think that I may be somewhat alone in my continued usage of Gens ace lipo batteries. If you care to join me, you can buy factory assembled Gens lipo battery packs from numerous vendors. Those of you comfortable with heavy soldering can save a few bucks by assembling your own packs from individual cells. In fact, most of my Gens Ace lipo battery packs were built with cells scavenged from certain DeWalt cordless drill batteries. Also note that Gens Ace lipo battery cells require specific chargers.

How to Test LiPo Battery Packs

Lithium Polymer Batteries (LiPo’s) have now been with us for many years and have become an essential part of this hobby. Their low discharge rate is perfect for devices that don't draw considerable current, and the cell's compact footprint makes them easy to squeeze into tiny devices. The challenge with LiPo batteries lies in their charge and discharge profile because unlike nickel or lead-based batteries, LiPo cell voltage is not self-limiting. Without a specifically designed charger, the battery voltage would continually increase until it bursts into flames (a generally frowned upon outcome in electrical design). Discharging LiPo batteries without proper protection is only marginally better, and will result in cell damage without restricting the operating voltage to a very specific range. If you want to test the condition of your LiPo battery pack then use a multimeter and you can test the voltage and mAh.

Look on the label on the LiPo battery pack. You need to find out the output voltage and mAh rating. The voltage figure is always a multiple of 3.7 and the mAh always a multiple of 2,100. For example, a LiPo battery pack using three cells has a voltage of 11.1 and mAh of 6,300, it is 7.4v lipo battery 5000mah. The figures on the label are the figures you can expect to get when you test the battery using the multimeter.

Measuring Voltage

To start, let’s measure voltage on a AA battery: Plug the black probe into COM and the red probe into mAVΩ. Set the multimeter to “2V” in the DC (direct current) range. Almost all portable electronics use direct current), not alternating current. Connect the black probe to the battery’s ground or ‘-’ and the red probe to power or ‘+’. Squeeze the probes with a little pressure against the positive and negative terminals of the AA battery. If you’ve got a fresh battery, you should see around 1.5V on the display (this battery is brand new, so its voltage is slightly higher than 1.5V).

If you’re measuring DC voltage (such as a battery or a sensor hooked up to an Arduino) you want to set the knob where the V has a straight line. AC voltage (like what comes out of the wall) can be dangerous, so we rarely need to use the AC voltage setting (the V with a wavy line next to it). If you’re messing with AC, we recommend you get a non-contact tester rather than use a digital multimeter.

Set the multimeter to read voltage. Check the two terminals on the battery pack to determine which is positive and which is negative. They are labeled "+" and "-" respectively.

Read the voltage output on the multimeter display. It reads the same as on the battery pack label. If the voltage is more than five percent less then it’s likely the battery is losing charge quickly as you have only just charged it.

Set the multimeter to measure mAh. Place the two sensors on the battery terminals as before. Read the mAh on the multimeter display. It is the same as the label on the LiPo battery. If the mAh is more than five percent below the figure on the label it’s likely you have a problem with your 3s 2200mah pack as it should not lose energy after just getting charged.

Leave the LiPo battery overnight. Do not use it as you need to see if it loses charge while not in use. A good battery pack has the same readings the next day.

How to test for aging lipos

As a possible rule of thumb, you might find that if a 3s has an IR more than around 50-60 milliohms, it is probably past its best. Based on my experience with 6s lipos, they seem to show other signs of aging before getting up to around 20 milliohms per cell (like the 3s), so perhaps around the same value 50-60 milliohms for the 6s pack as well.

The overall % of capacity seemingly dropping (ie. the charger will tell you that you pack has, say 20% left when you put it on charge, and yet you only took out 62% based on mAh put back in compared with rated mAh, so it only adds up to 82%)

You can’t measure the battery voltage without taking the battery packs apart because the voltage converter in the battery pack will provide a constant voltage (5.0V for USB, etc.) regardless of the battery voltage. However, you can estimate the battery voltage by determining when the power packs shut off. Lipo and li-ion cells are considered depleted when then fall below 3.3-3.5V, so the circuitry inside the battery pack should shut off then.

If you have direct access to the cells, you can also rely on the voltage info given by your hobby charger. When discharging, the Accucel displays the voltage, and that’s the battery voltage under load.

Charging Multiple LiPo Batteries With One Charger

In this tutorial, I’ll be going over everything you need to know in order to charge multiple lipo batteries. by basically using just one part that you don’t already have called a parallel charging board, you’ll be able to charge up to 6 Lipo batteries all at the same time.

How It Works

Here's a detailed schematic of a harness used to charge two 3s lipos in series. In series, the positive of the bottom battery is connected to the negative of the upper battery. Notice how this connection is made twice, through both the power harness and the balance harness. More on this later.

How To Para Charge

First you will need to build or purchase a parallel charge plug or board that the charge leads from each battery will be plugged into. The positive from each plug is hooked to positive and the negative of each plug is hooked to negative (parallel circuit). To keep things in reason, most will only build a plug or board that will support up to 5 or 6 batts maximum.

Things start to become a little congested as you can see with that amount of wiring and batteries, especially if you still want to use a fire safe charge container or bag.

My general rule is it's better to charge in parallel. With parallel charging, the batteries must have the same number of cells and a similar state of discharge. The same number of cells rule is easy for me because I keep all of my battery pairs permanently connected. For example in my Revo, my gens ace 2200mah 11.1v 30c are wired together in series all the time. My ESC only has one plug for the batteries. Same thing goes for a pair of my 4s batteries. They are permanently wired together in parallel. So regardless of the single pack configuration, all of my battery pairs are 4s before they hit an ESC or a charger. Makes life easier.

Here's an example of two of my 4s lipos "permanently" wired together. The stay connected to this harness all the time. In these pictures, I have a protective cap installed on the balance plug. This keeps that connector clear while I'm driving.

Requirements and recommendations for serial charging

- Serial wiring adapter for the main leads that matches your charger's output capabilities. Because serial charging effectively creates a larger cell count pack, the capabilities of the charger will limit the number of packs that can be charged in series. For example a 6s capable charger can charge 2x 3s pack in series. Charging 2x 4s packs in series would require an 8s capable charger.

- A wiring adapter for the balance leads is basically required and needs to have the same number of connections as the main leads adapter.

- All the packs you charge in series must be the same capacity. For example you could charge a 3s 2200mAh lipo, a 2s 2200mAh lipo and a 4s 2200 mAh lipo in series together, but you can not charge a 3s 2200mAh lipo in series with a 3s 3200mAh lipo.

- All the packs to be charged in series together need to be very close to the same voltage per cell. If I had to put a number on it I would say within .05V per cell.Serial charging is best suited for someone looking to charge flight packs made up of pairs of packs like 2x 3s 2200mAh packs used in a 500 sized heli.

Things You Should Not Do

1. Because the lipo cells are connected to each other throughout multiple batteries, you should never plug in a fully or half charged battery with a battery that’s dead. Basically, the farther apart the voltages are, the hotter the wires will get. So all of the batteries should be hovering around the same voltage.

2. Another important thing to remember, is that you can’t charge two completely different batteries with each other. You can mix lipo packs from different brand names, but the cell count needs to be the same, and the battery capacity needs to be the same.

if i understand this right a 3s 2000mAh 10c 12.4 battery contains inside it 3x 1 cells 2000mAh 10c ~4.15v packs (safe recommended charging voltage). So with those Lipo batterys that are now showing up i could take apart a larger pack like a 2s lipo batteries - 130c to get 2x 500mAh 65c - 130c ~4.35v (can be safely charged to 4.35v per cell) for a single cell rc model and say run in a hubsan quadcopter as a example provided it fits. This would be a massive improvment over the stock batterys of most single cell quads right? slightly higher volts with high discharge giving way more power at a cost of weight.

That’s it!

Hopefully this short guide gave you some idea what multiple charging is, and how to do it on your own in a safe fashion.

The Characteristics of Li-Ion/Polymer Battery

The nominal voltage of a Li-Po battery cell is 3.7V (about 4.23 V when fully charged). Two and three cell batteries are available giving us a choice of 7.4 or 11.1 volts. Li-Po batteries can provide substantial current, 6A 2200mah 3s lipo battery continuously and 12A for short (30-second) bursts. Li-Po cells have a flexible, foil-type (polymer laminate) case. Since no metal battery cell casing is required, Li-Po batteries are very light. Because of the absence of metal casing and less space utilized in intercell spacing, the energy density of Li-Po batteries is over 20% higher than that of a classical Li-ion battery and store more energy than nickel-cadmium (NiCd) and nickel metal hydride (NiMH) batteries of the same volume.

Care must be drawn in using Li-Po batteries. Their capability to provide high burst currents, lack of a rigid case, and overcharging sensitivity presents both electrical and thermal hazards. Intelligent chargers designed specifically for Li-Po batteries must be used to recharge these batteries. Overcharging a Li-Po battery will likely lead to explosion and/or fire. Li-Po cells must not be discharged below 2.75V per cell, or else the battery will subsequently no longer accept a full charge and may experience problems holding voltage under load.

Very little battery performance data seems to exist regarding the current generation of low-cost Li-Po batteries. Since we were unable to locate discharge or charge rate charts for the batteries, we decided to perform our own characterization.

Since lithium polymer (and lithium ion) are so sensitive to overcharging, the individual cells that make up the battery pack are charged independently. With NiCad and NiMH packs, the standard charging method is to apply a voltage and current across the series-connected cells so that the same current passes through each cell. The voltage across the entire pack is the sum of the individual cells voltages, but the cell voltages are not necessarily all equal. In fact, it is almost certain that they are not. Since nickel-based cells are relatively tolerant of some overcharging, there is usually no danger. It is not uncommon for one cell in a NiCad or NiMH battery pack to be dead, and yet the rest of the cells charge normally. What that means is in the case of an 8-cell pack, with the nominal voltage of each cell being 1.2 V (9.6 V total), if a charging voltage of 10.4 V is present, each cell would ideally receive 10.4 / 8 V = 1.3 V. If one cell is dead, however, the voltage across each cell would be 10.4 / 7 V = 1.5 V. That 15% increase can be handled by most NiCad and NiMH cells, but a 15% overvoltage applied to a lithium cells would eventually result in a failure, and likely a fire. Li-Po batteries are also intolerant of over discharging, and tend to die if discharged below around 2.5 V. In operation, controller circuitry should prevent the cell voltage from dropping below 3.0 V. Cell temperature should never exceed 90 °C in order to prevent the internal separator polymers from melting and allowing plate shorting through physical contact.

To the left is my Mini Pulse XT aerobatic airplane. It uses the 450 motor and a 3 cell , 11.1 V, 2100 mAh, Li-Po battery. Futaba 4-channel radio.

Early lithium batteries had a rather high internal resistance, and had rather low discharge rates. As with all technology that is doggedly pursued, significant improvements have been made to the point that the contemporary Li-Po batteries may be substituted in most systems for the original NiCad or NiMH batteries. Discharge rates of 20C or 25C are commonly available on the commercial market. You can find 20C on google, there are Gens ace 20C 2000mah lipo, best 2s lipo battery in the market. In battery discharge terminology, each "C" is a discharge current equivalent to the value of the energy capacity of the cell (it is not the abbreviation for the Celsius degree unit). In the case of a 1,200 mAh rating, 1C is equal to a discharge current of 1,200 mA, or 1.2 amps. A 10C cell can deliver a continuous current to a load of 10 x 1.2 A = 12 A during its discharge cycle. The E-flight 450 motor shown to the right would require atleast a 12C battery to deliver full rated power. This motor, by the way, is the one I use in my electric-powered sailplane (2-meter wingspan) and in my 4-channel aerobatic airplane (an E-flight Mini Pulse XT).

In my opinion, Lipo batteries are grossly overpriced, given the huge production volumes in effect. When you consider that almost every mobile electronic device and cordless power tool uses these batteries, the cost should be a lot lower. Maybe it is partially product liability insurance that manufacturers have to purchase that keeps the prices high, but I just paid $50 each for two 3-cell (11.1 V), 2,100 mAh packs. That is at least 2x to 3x what is should be costing at this point in the lithium cell evolution.

RC Battery Buying Guide For Your RC model

What Is mAH rating?

All RC batteries come with a certain capacity to store electric energy for a specific period of time. This capacity of the RC battery is expressed in terms of mAH. mAH stands for Milli-Ampere Hour and the rating defines the ability of the mobile battery to perform for a specific period, typically one hour. The higher mAH ratings are sometimes misunderstood as how fast the current is drawn from the battery. Rather, the higher mAH ratings indicate how long the current can be drawn from the battery until it is completely discharged. This is one aspect that almost every mobile phone user must consider before purchasing a replacement battery.

A RC battery's mAH rating determines the period or the number of hours or days a battery can keep the mobile phone alive on a single charge. For instance, a 1000 mAH battery is capable of providing 100 milliamps for a period of 10 hours, and a battery with lipo 7.4 v 5000mah capacity can supply similar volume of current for a period of 20 hours. The larger the number of mAH rating on the battery, the less frequent would be the need to recharge the phone. The number of hours mainly varies across different OEMs or manufacturers and is also governed by the usage patterns.

mAH Rating and Types of Battery

Different RC batteries with the same mAH rating need not have the same shelf life. The technology used in manufacturing the battery, the usage pattern, the RC software, etc. determine the overall performance of a RC battery. mAH is just an indication; it need not always translate into real-time results. Buyers should look into their RC needs and power requirements when buying a RC battery.

Understand battery terms when buying an RC battery.

mAh: Milli Ampere Hour. This is basically the electric charge transferred by a current of one milliampere for one hour. The higher the mAh, the longer a battery will last per charge. This is the one part of a battery that you can change without damaging the heli.

Volt: The electrical pressure. Basically this determines how much power can flow to the motor. For lipo batteries the voltage comes in multiples of 3.7 volts, or 3.7 volts per cell.

Cell: An independent 3.7 volt battery.

Litium-Ion (Li-Ion): a type of battery that has a rigid cell structure and shape. It is safer than a lipo battery, but not as efficient.

Lithium-Polymer (Lipo): a type of battery with a flexible cell structure and shape. Lipos can catch fire and explode if mistreated or dropped on a hard surface. Be careful! Although more dangerous, they are more efficient than li-ion batteries and can come in practically any shape with the same cell count.

My tricopter has a max current draw of around 30A – 35A, and all of the batteries below meet the requirement.

From these data, you can create some very interesting and useful graphs, for example I usually do

Density, which is capacity per gram (= capacity / weight), and

Value, which is capacity per dollar (= capacity / price)

From the above graphs, if I am only going for best performance and not worry about the price, I would definitely go for 2650mah lipo, 3000mah 3s lipo batteries lipo, or 3300mah lipo. Also 4000mah lipo might be a good choice too due to its outstanding value.

These graphs tell you some insights into which battery has the highest price/performance ratio, but it doesn’t tell you whether this is the best battery for your RC aircraft, quadcopter or tricopter. To do that, we need to create a mathematical model.

Recommend Gens Ace LiPo Battery

Gens Ace LiPo batteries are designed for customers seeking the ultimate in battery performance. Building upon the highly rated Admiral brand of LiPo batteries, Gens Ace offer a higher continuous discharge rate and lower internal resistance. While the majority of our products are sufficiently powered by our standard Gens Ace batteries, we offer the Gens Ace series for enthusiasts who are running high current draw devices or hobbyists who want a "top of the line" LiPo battery.

Compare a LiPo to a NiMh/NiCd

The Lipo packs are lighter than the equivalent Nimh/Nicd packs. Lipo batteries are like little envelopes, and as such they are encased in a strong plastic box for gens ace batteries, to protect them from damage. They don't need to be charged just before use, you can charge them days in advance and run them without any need to repeak. They shouldn't be run completely flat, and some ESCs have a setting for Lipo to ensure you don't flatten them. You don't need to discharge them before topping up either. They are generally a bit more punchy as they can deliver more power on demand.

NiCD: And old technology that is not used very often today. They have a 'memory', so if you only use don't discharge the battery 100%, the next time you charge it, you will less capacity and that will keep on happening till there is nothing left.

NiCD: And old technology that is not used very often today. They have a 'memory', so if you only use don't discharge the battery 100%, the next time you charge it, you will less capacity and that will keep on happening till there is nothing left.

NiMh: Still used today, and it for people who don't want to go the LiPo route or often recommended for beginners. Chargers and batteries are quite cheap, and are generally considered safer so long as you use a good charger. These are generally sold at 7.4v 5000mah lipo battery packs, which puts out 7.2v.

LiPo: The bees knees at the moment. They are lighter, have a higher voltage for the weight, and can give the motor more amps. Precautions do need to be taken when charging because if they are charged incorrectly, they can catch on fire. So long as you are careful and use an appropriate charger with the right settings (such as charging a 3 cell as a 3 cell, not a 4 cell) and have a voltage cut-off on your ESC you will be fine. If the voltage gets down to under 3 volts per cell, then you damage the batteries which is why you need the voltage cut-off set up on your ESC (most have this built in), which turns your cut power when it detects around 3 volts per cell.

When you are trying to compare a LiPo to a NiMh/NiCd, you have to understand that from a battery standpoint there are two things that improve your guns performance. In regard to the above batteries mentioned:

Battery A = 7.4v, 18C, 1700mah = 30a Discharge

Battery B = 11.1v, 15C, 2000mah = 30a Discharge

Now lets throw a couple other batteries in the mix.

Battery C = 9.6v, NiMh/AA, 1700mah = 20a Discharge

Battery D = 9.6v, NiMh/SubC, 4400mah = 35a Discharge

Battery E = 7.4v, 10C, 4400mah = 44a Discharge

Battery F = 7.4v, 30C, 4400mah = 132a Discharge

Lets say you have two guns, one with an ICS Turbo 3000 that uses say 18a max. Then you have a second gun with the black hole of airsoft guns known as a Systema Magnum which uses up to 40a (these are not to be technically accurate power draws for the motors, just making an example here).

In gun A, all of the batteries supplies sufficient amperage to meet the motors maximum draw, therefore it's almost purely a matter of voltage at that point. The only other catch is the fact that batteries don't put out a consistent amount of power. The lower you drain the battery, the less power it's putting out. To that end, LiPo's put out a higher voltage for longer than NiMh/NiCd's which is why they seem to perform better that you would think.

In gun B however, the story is different. Only Battery F is capable of putting out enough amperage to fully meet the motor's demand, although battery E is close. However in this situation, Battery E will outperform Battery A because it's putting out more amps. In the same manner, Battery F will likely outperform Batteries C and D because they aren't enough supplying enough amps. Even if you add more cells to Batteries C and D to increase them to 10.8v or 12v, they still aren't providing any more amps which means Battery F is still going to give it a run for it's money.

So, to say a 7.4v LiPo is close to 9.6v NiMh or an 11.1v is close to a 12v NiMh, depends on the output of the batteries and the draw of your motor. An 11.1v LiPo with a 100a discharge will slaughter a 12v NiMh that's putting out 20a in any gun that can draw more than 20a. Regardless of battery chemistry, one thing to keep in mind is that increasing the voltage of the battery causes damage to your guns entire electrical system. Increasing the amperage does not cause damage to it, however it does allow your motor to run at 100% of it's capacity which means it may fail sooner than it normally would, especially if it's a cheap motor.

For the record, my two primary batteries are an 11.1v, 20C, 4400mah and a 7.4v, 30C 5000mah battery. Those batteries put out 88a and 150a respectively in bursts. I've yet to burn out a motor.